Marine Engine Bay Noise Reduction - Suitable Insulation Products for Marine Engine Bay Noise Reduction

marine engine baymarine engine bay insulationmarine engine bay noise reductionmarine engine bay sound insulationnoise reductionsound insulation

Marine Engine Bay Noise Reduction - Suitable Insulation Products for Marine Engine Bay Noise Reduction

An unshielded diesel inboard engine can reach upto 110dB. This is on par with several types of construction equipment. The government usually advise against prolonged exposure to in excess of 95dB. If your marine vessel is noisy, there is no need to replace the engine.

Aftermarket boat sound insulation products are becomming more apparent with their one-off fit requirement, whilst providing lasting acoustic results. Using a combination of materials you can reduce the dB reading by 30-40 dB creating an enjoyable motoring experience for you and the environment around you.

If you are reading this page we are fairly confident you are looking for a way to reduce sound in your marine engine bay. We are hear to offer advice on the different products available for marine engine bay noise reduction.

First of all, we recommend you inspect the marine engine bay area for the possible thicknesses of marine engine bay sound reduction products available to be selected for the fitout. Usually in most areas there is at least 50mm around the engine. It is also recommended to understand the temperature of the engine bay area so you can be sure you are selecting insulation products which are capable of these temperatures.

Sound Deadening:

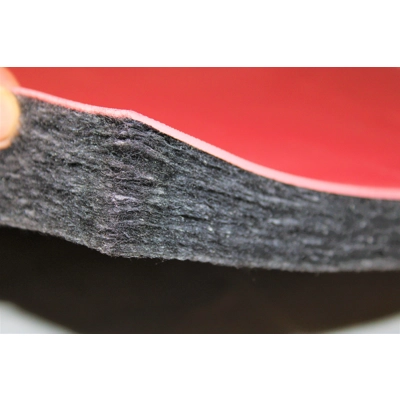

There are many sound deadening products on the market for marine engine bay noise control. We have developed a sound deadening material which is both waterproof and UV stable with an aluminium and filmic barrier outer layer and a butyl inner core layer. This marine engine bay insulation product is known as ButylMAT and comes on rolls or in sheet form. It is manufactured in the UK and is capable of temperatures from -40C to +90C. It will deaden the marine panels and if fitted with 100% coverage it will provide a barrier layer for sound transmission. You can layer this insulation material in areas of high noise, if you are trying to ultimately silence the engine.

Additional barrier layer insulation:

You can also fit post sound deadening an additional barrier layer in your marine engine bay. The product we would recommend for this is known as DeciLAM and is used as a barrier layer in many applications. It is 5Kg/m2 and comes in rolls which are 1.2m wide. It is self adhesive and tested to euroCLASS B-s2-d0 for flammability. This means it resists fire. Coming in at 3mm thick and rated at 27dB reduction, it is still flexible enabling it to be fitted around corners. The temperature performance is -40C to +60C

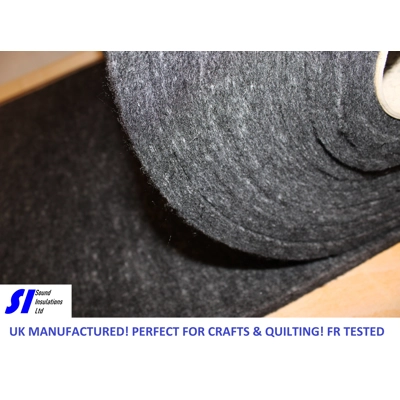

Acoustic absorber material:

After you have fitted these marine engine bay noise reduction products, it is advisable to fit a waterproof acoustic absorber to reduce the sound pressure within the enclosed space of the engine bay. For this we recommend 3m Thinsulate, it is hydrophobic in nature and is flame retardant to FMVSS302.

Thank you for reading. All of these marine engine bay noise reduction products are available on www.boatinsulation.co.uk and they are all manufactured in the UK

Posted by Boat Insulation

Wednesday, April 10, 2024

0 Comments

Optional, for replies

No comments posted yet, check back soon.

Featured Products

VBLam33 Boat Marine Laminate Insulation Sound Proofing The..

£65.99

VBLam23 Laminate Boat Sound Deadening Sound Proofing Insul..

£53.99

Marine Self Adhesive Body Protection Heat Shield Exhaust 5..

£41.99

ButylMAT Boat Sound Deadening Material Insulation 1.7mm Th..

£10.49

SIFELT Marine Sound Proofing Wadding Thermal Insulation 1..

£23.99

ButylMAT Boat Sound Deadening Insulation 1.7mm Thick 10 Sh..

£10.99

SIFELT Marine Boat Acoustic & Thermal Insulation 1m x 3m 3..

£23.99

Marine Self Adhesive Acoustic Heat Shield 7mm Thick Boat M..

£70.00

Blogs

Class 0 marine insulation materials by Boat Insulation

Read More

Mass Loaded Vinyl - By Sound Insulations for Boat Insulation Applications

Read More

Enhance Your Boating Experience with Quality Boat Insulation

Read More

Boat Insulation From Cruise Ships to Narrowboats - Welcome to Boat Insulation

Read More